The housing market is building snowflakes: How an industry of endless one-offs is holding our society back

By Aaron Holm and Nelson Del Rio,

Co-CEOs, Blokable Inc.

The following post breaks down the high cost of building housing as part of a series exploring the root causes of the U.S. housing crisis and how private and public sector collaboration can chart a different course.

In mid-2018 we met with Washington State Governor Jay Inslee to discuss the insatiable need for affordable housing in the Pacific Northwest. We gave him a tour of Blokable’s prototype factory in Vancouver, Wash., and shared our R&D work to reimagine how housing is built. Afterward, we drove up to Seattle in a rented Nissan Maxima, wondering aloud what it would cost to build our rental car from scratch in a driveway — exactly how nearly all housing is built today.

We would have to design, engineer, and fabricate all of the car’s systems and components, specify and source the materials, identify the regulatory requirements and work with different agencies to test our systems and sign off on safety and environmental requirements, create a working set of engineering drawings to track the build, order the equipment necessary to complete the assembly, and hire at least a small team of people to put the car together. A car that retails for just under $35,000 would cost tens of millions of dollars to build, and there would be no guarantees of quality and reliability.

Every time a new residential real estate project appears on the landscape, it’s a bespoke process that can directly involve hundreds of people, including a developer and a general contractor, various architects and engineers, and the investors who are funding the project. For each participant in the process, the singular goal is to extract a profit from that specific patch of dirt, and their profits are circumscribed by the value of the land, the applicable building regulations, and the prevailing labor and capital costs.

The result of this one-off approach is soaring project costs that make housing simply unaffordable to most people in many parts of the U.S. Conventional housing development is like building a snowflake every time. And if the glut of empty luxury condo towers in downtown San Francisco is any indication, many of these snowflake projects are indeed melting as soon as they touch the ground.

How did this one-off approach to development take shape? Everything from ovens to stereos were all once clunky prototypes built as one-offs in the same location as their eventual use. Over time with innovation, standardization, and market demand, they evolved into products. In the early days of the automobile and aviation industries, prototypes and projects were built at high cost and yielded low quality results that resembled the current market products in their most basic functionality: they could drive and fly. Early automobile and airplane prototypes were unsafe and expensive. But through investment in product design, engineering, prototyping, and manufacturing, these prototypes eventually evolved into products. Increasingly stable designs and specifications enabled greater standardization, repeatability, and mass production resulting in lower costs, higher quality, and broader distribution.

Coupled with clear market demand, this standardization led to the formation of entire industries to build roads and airports, manufacture tires, test safety under federal guidelines, and so on. If you visit the automotive and aviation manufacturing hubs around Detroit and Seattle you’ll find vibrant supply chains competing for business and investing in innovation to provide better products and services. Continuously improving engines, seats, windshields, and bathrooms. All of this activity creates ever-improving products and fierce competition for performance, quality, and price.

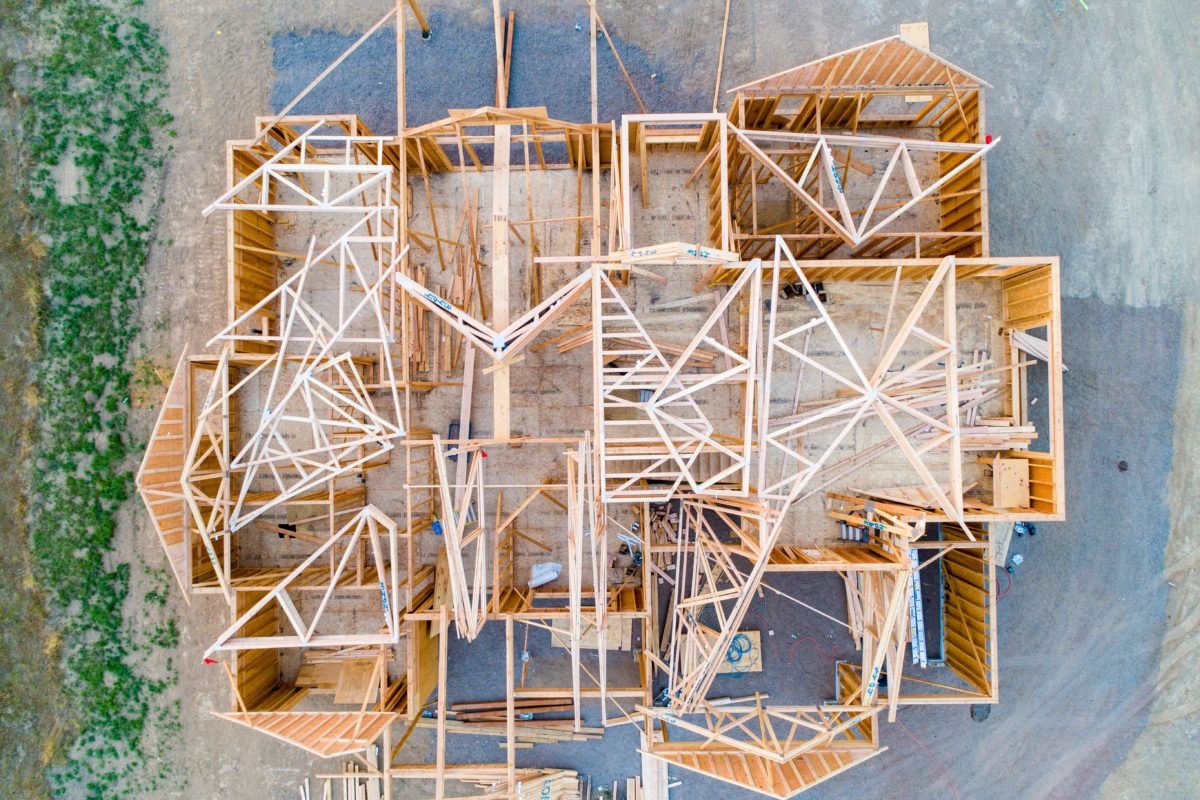

If we compare product manufacturing in the automotive and aviation industries to how we build housing — whether it is an Accessory Dwelling Unit (ADU), single family home, multi-family apartment building, or a high rise — the steps in the process are largely the same. To simplify the housing development process, let’s assume the land is entitled, there are no environmental mitigation issues, financing is secured, and development will not be opposed by regulatory agencies or local city council. What does it take to build a snowflake?

Let’s look at the absolute bare minimum of steps in the process from the perspective of the developer. Broadly speaking, the developer identifies and ties up the site, conducts preliminary site review and discussions with impacted parties, manages entitlements, financing, and the project approval process for the site, oversees all building and owns the project along with any equity investors they have brought in to finance the deal. With respect to the building process itself, the developer will partner with an architect to work up a site massing and design that will satisfy the intended program — the mix of units, floorplans, common spaces, revenue generating and non-revenue generating space — as well as the code requirements for the building and the site. Once the basic architecture is in place, the project heads over to engineers, which are typically separate firms with separate contracts, costs, regulatory oversight, and liability, to specify structural engineering, MEP (mechanical, electrical, plumbing), and site and offsite engineering.

With the initial design and engineering complete, the developer sends a construction set of drawings to a general contractor (GC) for final pricing. The GC will take the specifications and build out a schedule and budget to determine how much work they intend to do themselves (self-perform) vs. how much work they will contract out to sub-contractors (subs). The GC will oversee all of the work necessary to build this custom-designed and engineered project on-site, including civil, foundation, pulling utilities, framing, rough-in and waterproofing, siding and cladding, roofing, windows and doors, MEP, paint and trim, fixtures and finishes, and ultimately certificate of occupancy. It is important to note that at this stage the GC’s quote is just an estimate. We haven’t built anything yet.

With approved drawings, financing, budget, and schedule in hand, the developer can start the snowflake build. Every step listed in the paragraph above must be completed by the corresponding specialists, and getting the work done on schedule is much more of an art than a science. Each contractor and subcontractor has their own contractual obligations, risks, and liability. Getting to the certificate of occupancy means the developer has navigated the process and can now bring in buyers or renters to start paying off the decades of debt that were secured to finance the build. When the developer moves on to the next project, all of the steps must be performed again, without exception. The finished project may be beautiful, energy efficient, or last 100 years, but it will still be a one-off.

All of this work is done for every project every time, regardless of size. A home or apartment is not more complicated than a car or plane, and while the unique attributes of individual sites and real estate do add challenges to repeatability, it is possible to decouple the building from the dirt.

We can’t be surprised that building costs for new housing continue to escalate. We can’t be surprised that it’s even more expensive to create affordable housing. Yet we continue to shrug our shoulders and say, “That’s just how it is.” We dig around the edges of the problem, foraging for scraps by looking for cost savings in commodities, underpaying labor, cutting corners on quality and performance, and building on cheaper land further and further from work and community.

Housing development is antiquated and the only group benefitting is the real estate development and building industry, who in fact have every incentive to restrict the supply. We’re making Version 1 of the oven, stereo, car, and plane over and over again, in a housing market that is chronically under-served. The failure to build adequate housing has generational effects on health, education, and opportunity.

There has to be a better way. We have to re-imagine the housing market and build better. More on that to come in our next post.